NIPCO™ Air Hybrid

NIPCO™ Air Hybrid Technology Dyeing Padder

The first dyeing padder with flexible area controlled pressure setting across the width

Advantages:

NIPCO™ System based on AirHybrid Technology

- Homogenous press force distribution over entire material width

- Individual adjustable edge areas

- Precise adaption to material width

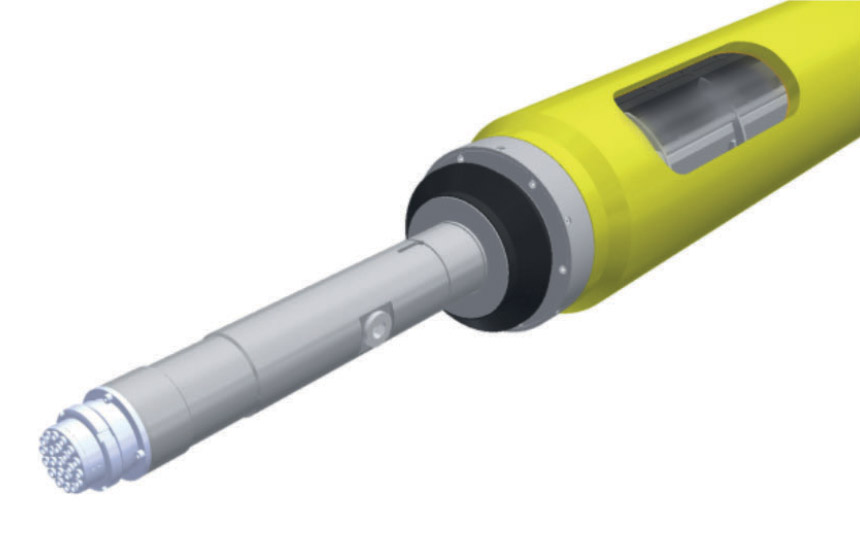

- Highly flexible sleeve system with different surface materials

- Cantilever execution with sleeve quick change system (CONEX)

- Closed Loop – operation possible

Technical Data:

- Linear loads: 10 - 50 N/mm

- Roller widths: 1000 - 4000 mm

- Roller diameter: 265 / 300 mm

Applications

A typical application for the NIPCO™ AirHybrid roller is its use in a padding / dyeing station or during finishing and dewatering. Due to its flexibility, only one NIPCO™ AirHybrid roller for padding or dyeing station is required. A conventional roller withdifferent sleeve system acts as counter roller.

Compared to conventional padder stations with 2 bending compensating rollers, the service and maintenance costs are significantly reduced.

Due to the cantilever version it is no longer necessary to remove the roller for a sleeve change. The sleeve quick-change system (CONEX) allows to shorten set-up / downtime for cleaning and sleeve change to the minimum.

The cleaning of the used sleeve can be done outside the machine and does not affect its availability. Today’s increasing quality requirements demand technologies that guarantee maximum production reliability and individual adjustability.

The NIPCO™ AirHybrid roller meets these criteria in all areas and applications.

Their advantages are decisive for a reproducibly high product quality.

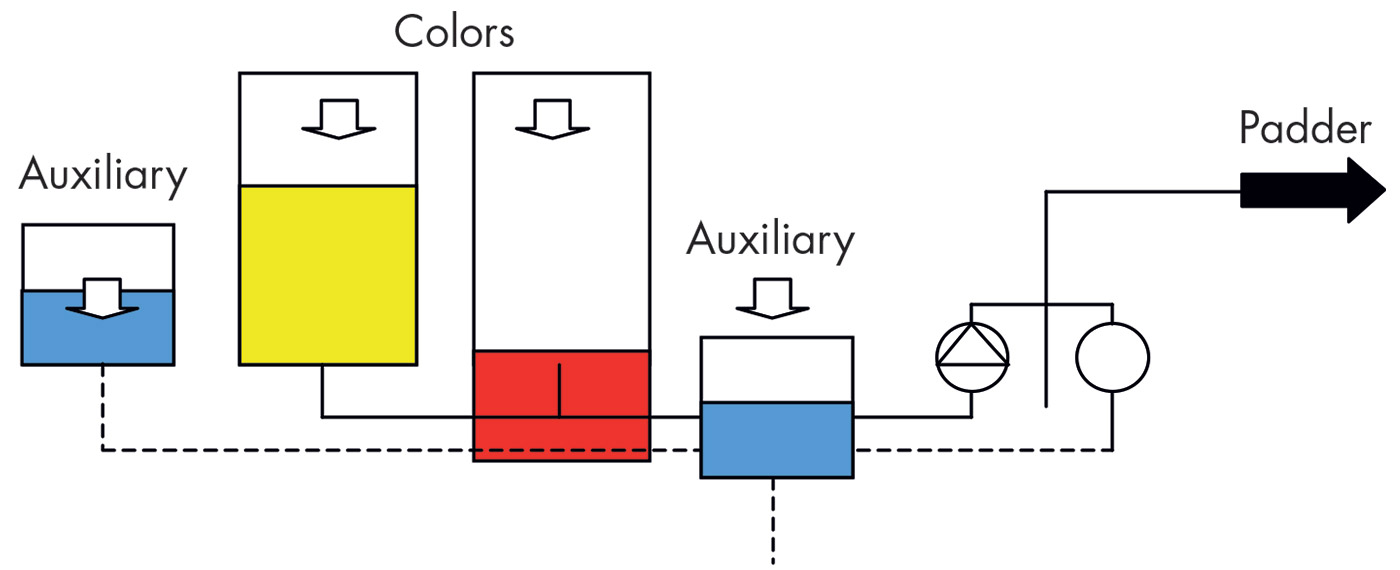

Chemically nothing changes from the traditional preparation of dyeing baths that are managed by the metering pump that mixes the auxiliaries and the color before entering the impregnation tank where the fabric is squeezed from the small rubberized rollers immersed in the tank to facilitate the penetration of the dyeing bath inside the fibers that form the fabric, before passing between the squeezing cylinders of the padder.

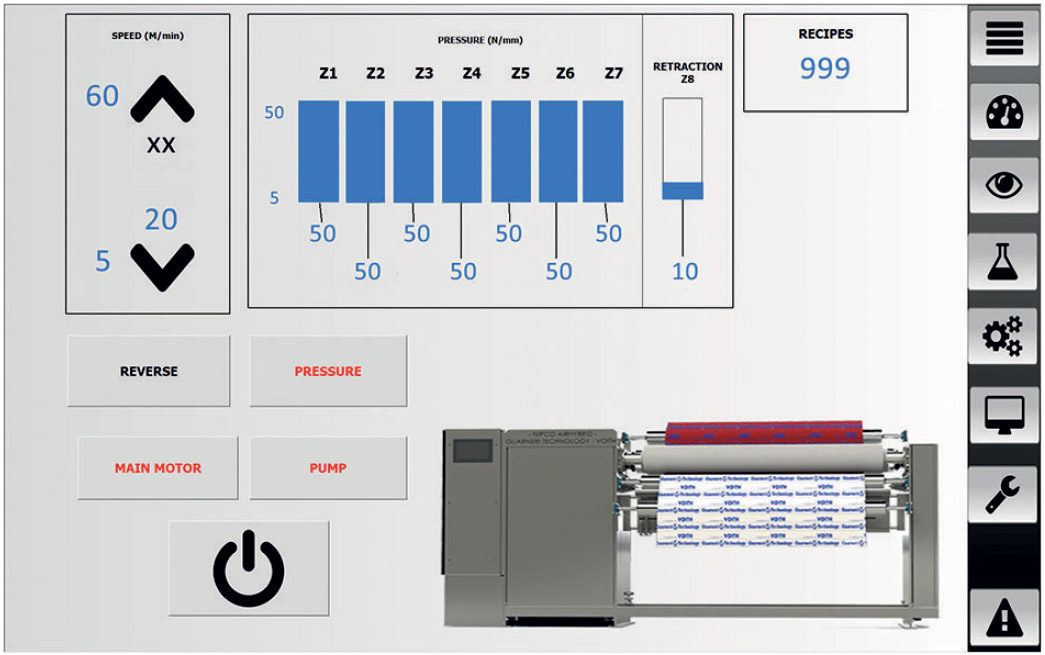

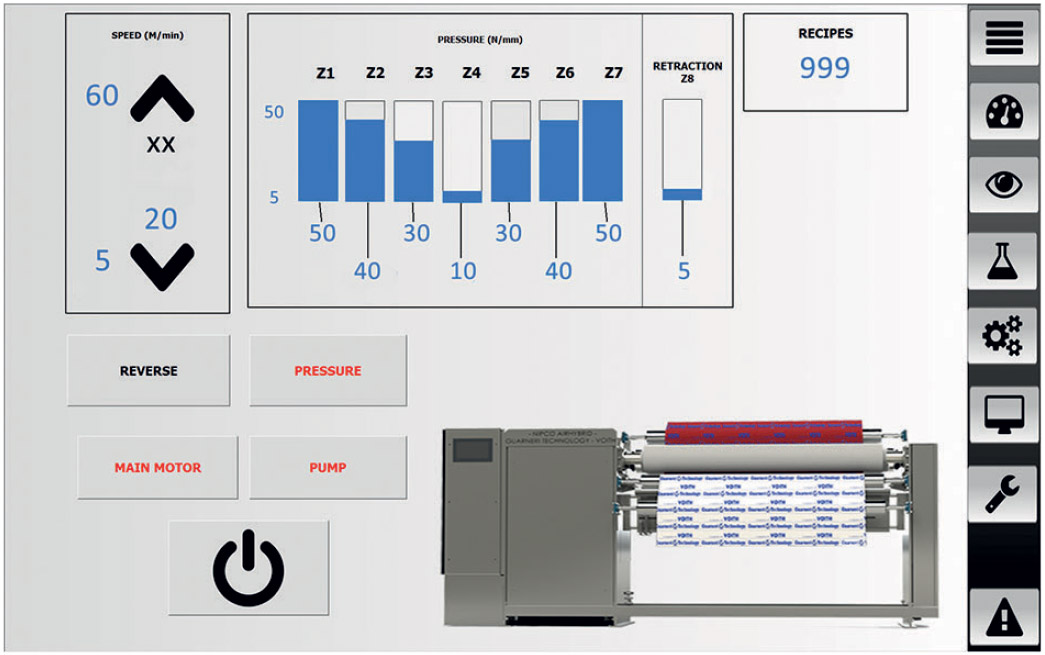

Force distribution

This roller concept is characterized by its individually adjustable force distribution.

The technology enables optimum pressure distribution regardless of the pressure level. The ideal shape pressure characteristic results in a uniform pressure over the width with perfectly reproducible results. Strips are eliminated by an advanced NIPCO™ support system. The pressure characteristic of the roll can be adapted to the process requirements as needed. Edge areas can be actively loaded or unloaded.

If the process requires a different force distribution across the width, the support system can be controlled individually. This can also be done optionally in combination with a closed loop measuring system. The exact limitation of the working width also allows an adjustable transition of the edge area at different material widths. A significant improvement in the process is the result.